Find out how to select the correct loading dock leveler, also known as dock plates, for your facility. A recessed dock leveler has a wider range of operation, it is the best choice to accommodate a wide range of bed heights. Only choose the edge-of-dock (EOD) leveler if the facility operates within the EOD’s narrow range of applications.

Suggested Article:

Do I Need To Replace or Repair My Dock Leveler (Dock Plate)?

Loading Dock Levelers | Loading Dock Plates

Dock levelers have long lives and contribute significantly to facility efficiency. It is important to provide accurate specifications for the dock levelers, including:

1. Length

2. Width

3. Lip projection

4. Load capacity

5. Activation system

6. Environmental capability

(Blog Post: What is a Dock Leveler?)

1. Dock Leveler's Length

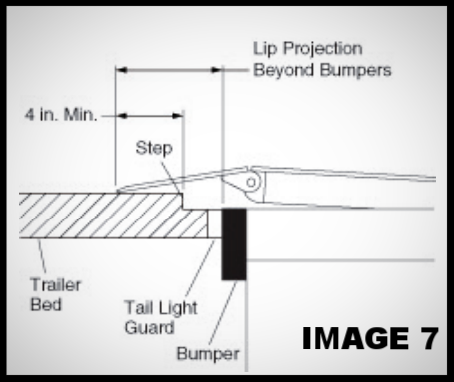

The length of the dock leveler is an important determinant of the dock leveler slope. This slope must be less than the maximum grade capability of the loading equipment. The length of the lock lever is based on the maximum height difference between the loading platform and the truck beds. dock levelers are available in lengths from 5 to 12 ft. The most popular length is 8 ft, which is suitable for most applications. The normal maximum grade operation for a manual pallet truck is 7%. For an electric pallet truck, the normal maximum grade is 10%. For an internal combustion forklift, the normal maximum grade is 15%. Consult the equipment manufacturer for maximum grade recommendations.

Remember: These normal maximum recommendations may vary depending on equipment specifications or design changes. The lengths shown in the loading dock equipment table below are the minimum dock leveler lengths required to keep the dock leveler ramp slope within the capability of the loading equipment.

For height differences or loading equipment not shown in the figures, the minimum dock leveler length is the height difference divided by the equipment’s maximum grade capability.

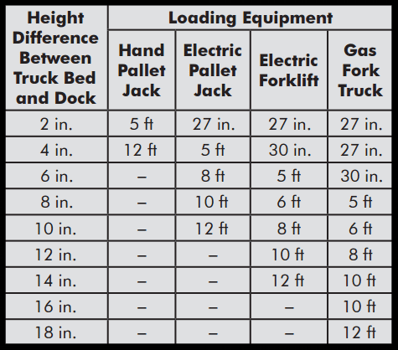

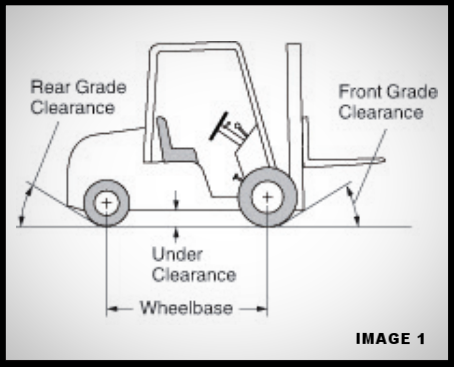

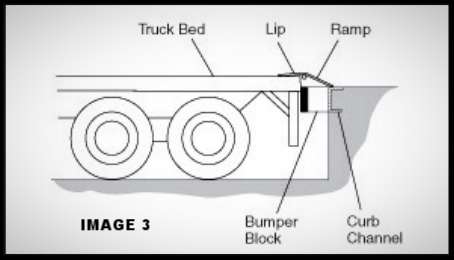

Forklifts and pallet trucks must have sufficient ground clearance to move freely and safely over a dock leveler (see Image 2 and Image 3). It is especially important to check the ground clearances of pallet jacks on EOD dock levelers. Pallet jack clearance is less of a concern on recessed levelers. If there are concerns about clearances, consult with the loading equipment supplier.

2. Dock Leveler's Width:

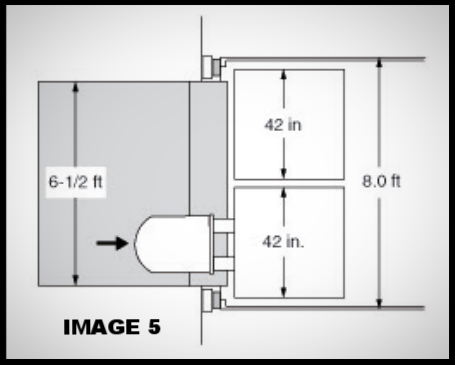

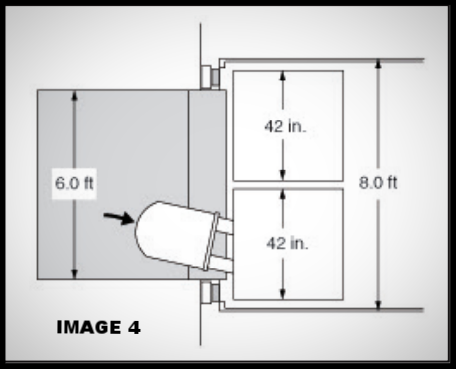

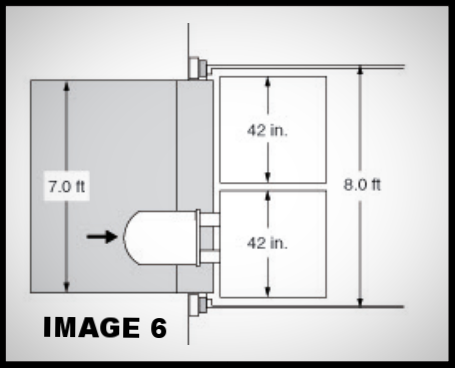

Dock levelers are available in standard widths of 6 ft., 6-1/2 ft. and 7 ft. The most common width is 6 ft., which suits most applications. However, 6-1/2 ft. and 7 ft. wide dock levelers are becoming more popular for wider trailers and side-by-side pallet arrangements (see Image 4, Image 5, and Image 6).

7 ft. wide dock levelers (dock plates) provide the best access for below-dock loading and end-loading side-by-side pallets. The end of the dock leveler lip should taper from 7 ft. to 6.5 ft. wide in order to service narrow trailers. However, it is not always necessary to taper the lip due to the standard trailer width increasing to 96 in. Maintaining the full width allows for the greatest maneuvering space and eliminates the dropoff area created by the taper.

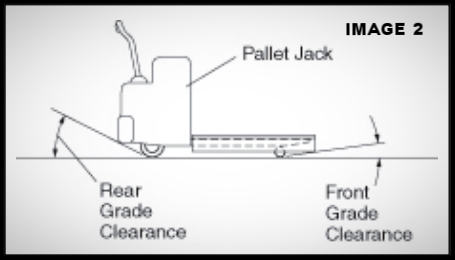

3. Lip Projection

The dock leveler lip must extend at least 4 in. into the truck per ANSI MH30.1 (image 7). A standard lip is 16 in., which projects 12 in. in front of the dock bumpers. Longer lips may be needed to accommodate the special rear step and rear door configurations on some trailers. The step of a refrigerated trailer may require a lip projection that is 14 in. or longer past the dock bumpers.

4. Load Capacity

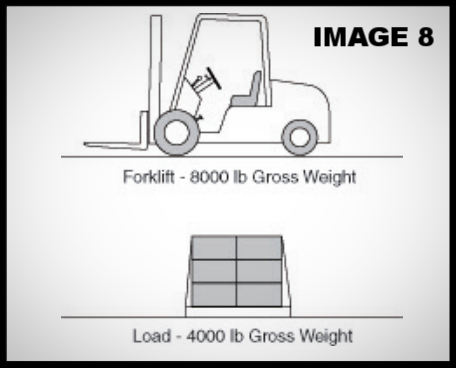

The load capacity of the dock leveler depends on the gross vehicle weight (GVW) of the forklift. For light to normal usage, the minimum required dock leveler load capacity equals the forklift GVW x 2.5. For normal to heavy usage, use a multiplier of 3 to 4. GVW = Weight of forklift + Weight of maximum load Load Capacity = GVW x 2.5 Example: 12,000 lb forklift gross weight + 6,000 lb gross load = 18,000 lb x 2.5 = 45,000 lb load capacity.

If the exact capacity is not available, use the next higher capacity. Using a higher-than-required load capacity will extend the life of the dockleveler. The following conditions affect load capacity:

• Each dock position serves eight trucks or more each day

• Forklifts do not drive straight onto the dock leveler

• Forklifts with three wheels are used

• Forklift speeds exceed 4 mph

• Forklifts are equipped with front end attachments or fork side shifters

5. Activation System

Push-button activation is the most ergonomic and safest type of dock leveler activation system. Manual or spring counterbalance activation should be used only when electrical power is not available. Push button-operated dock levelers may be less expensive over the long term as they require less service.

6. Environmental Capability

On inside/outside docks at temperature-controlled facilities, use perimeter weather seals to help prevent outside air from entering the building. At refrigerated facilities, the underside of the dock leveler ramp should be insulated. Condensation on the underside of the ramp causes corrosion and structural problems. Expanded foam insulation helps prevent the warmer outside air from condensing on the underside of the ramp. Insulation also saves energy by minimizing the loss of refrigerated air.

7. Optional Features for Dock Levelers/Dock Plates

Consider adding optional features to increase the effectiveness of your dock leveler/dock plate installation.

7.1 Increase the Lips Length

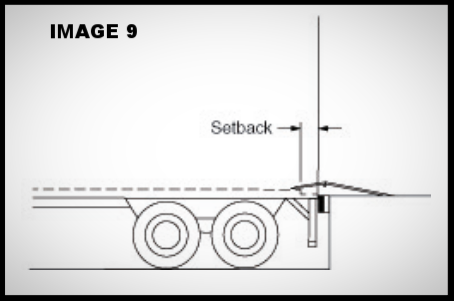

Dock levelers are normally supplied with a 16 in. lip plate that will suit the majority of applications. Lip length can be increased to 18 in. to 20 in. projecting out further from the dock face. Increased lip projection is necessary to deal with dock bumper projections of more than 4 in., substantial dock and truck bed height differences, and setback internal truck beds─typical with refrigerated trucks and trailers.

When loading or unloading a truck with a setback internal truck bed such as a trailer with swing doors, the lip must be sized to ensure lip contact with the internal bed. If the lip does not project over the internal setback and therefore rests on the step below the internal truck bed, the material handling equipment will strike the edge of the step up to the bed on every entry, making product transfer both rough and inefficient.

7.2 Side/Rear Weather Seal

Neoprene strips attach along the sides and/or rear of the deck assembly to better control the climate. The preferred weatherseal to protect against rodent entry is a brush seal.

7.3 Galvanizing

The zinc metalized spray process produces the optimal finish. Each dock leveler component is galvanized before assembly to provide complete protection. Galvanizing is commonly used in facilities that handle corrosive materials or are near harsh environments such as saltwater.

LOADING DOCK, IN. SERVICE PHOTOS:

The professional technicians at Loading Dock, Inc. have wide experience in fixing worn-out and rusty dock levelers. To ensure that your dock levelers are in the best shape, rusting should be given proper attention.

The proficient servicemen of Loading Dock, Inc. have been in the loading dock equipment service for over 4 decades. They have broad knowledge in providing repairs, installation and maintenance for all brands and types of dock levelers (dock plates).

For more information, please give us a call at 973-471-4060 or email us at info@loadingdock.com.

![]()

We service Northern New Jersey (Bergen, Passaic, Union, Essex, Morris, Hudson, Hunterdon, Somerset county/counties), Manhattan, New York City, Brooklyn, Queens, Staten Island, Bronx, Westchester and Rockland.