Although it may be tempting to save a few dollars and some time by skipping out on regular loading dock equipment maintenance, there are many downsides whenever there's an equipment failure. Regular maintenance of your loading dock equipment will not only help prevent workplace accidents but it can also help to keep equipment in good, functioning condition, eliminate major repair costs, improve productivity and increase profitability as well.

Loading dock equipment is designed to improve safety and efficiency during the material handling process, so it is crucial to invest in these important assets not only to keep workers safe and enhance business operations but also to reduce costly repairs against using the equipment to the point of failure and replacement. It is also important to keep in compliance with laws and regulations.

Benefits of Maintenance Plans in Loading Docks

The benefits of planned maintenance are higher than working on a reactive approach. A good maintenance system should include written instructions for regular inspections of equipment with documentation of the date, time and type of equipment inspected, as well as who carried out the inspection. Documentation is very important to verify that hazardous conditions were corrected. Use checklists to highlight and prioritize concerns to look for and follow all routine maintenance practices of equipment, to prevent incidents due to loading dock equipment failure. Everyone in the working place, including managers, owners and employers,must remember that laxity in terms of maintaining tools, equipment and the overall workplace can be not only dangerous but criminal if it breaks the federal labor law.

Even though it might be tempting to skip routine inspections or avoid minor repairs to save a small amount of money initially, an unsafe workplace can cost more in the long run in terms of loss of productivity, fines, total equipment replacements and even employee injuries. On the other hand, planning maintenance on a regular basis has a lot more benefits starting with the economic, because a consistent, planned service can improve overall safety and performance of the loading dock equipment.

Economic Benefits of Maintenance Plans in Loading Docks

There is no way to anticipate an exact budget for a loading dock equipment maintenance program, however, you can start with allocating more man-hours towards servicing equipment and the parts and items needed for routine adjustments and maintenance. It is possible that you might need to hire additional staff or hire an external service. The advantage of keeping a maintenance crew on a scheduled basis is that this will help you reduce overtime costs and routine tune-ups will also prevent large-scale and costly replacements. Pre-planned approaches will also increase safety for your employees. There is a 30% death rate related to this activity, which shows how dangerous maintenance at loading docks can be if it is not done properly or the staff is not properly trained on these procedures.

The reduction in maintenance costs can range from 15% to 98% and the return on investment is very favorable. There are other significant savings such as 35% to 45% reductions in downtime and 65% to 95% reductions in defects. Not all loading dock equipment needs the same frequency of inspections and maintenance, but it is a fact that assets kept in good condition do perform better and lead to improved efficiency, and result in longer life use.

Planned Maintenance Programs for Your Loading Dock Equipment

It is only by establishing a plan for scheduled maintenance, that facilities will see numerous long-term benefits, such as longer equipment life, fewer interruptions to productivity, and better equipment efficiency, aside from improved work conditions and safety for employees.

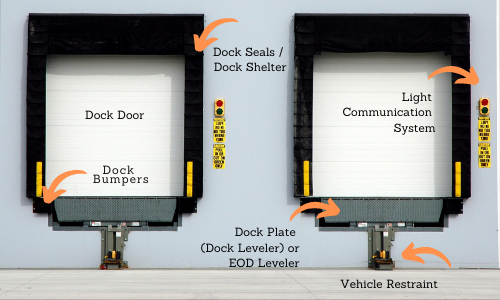

With an effective checklist, both facility managers and technicians can inspect loading docks and evaluate the performance of dock levelers, vehicle restraints, and dock seals or shelters to address potential hazards or defects on time and prevent any incident.

By establishing a planned maintenance program that covers equipment inspection, lubrication, cleaning and any needed adjustments that may be required, you will keep the loading dock area operating efficiently and safely for sure. In addition, if you make a visual structural inspection of the dock leveler platform, rear hinges and lip assembly, you will be monitoring the structural integrity of the loading dock equipment.

Based upon the usage of the equipment is how you can program your loading dock maintenance program frequency. For example, the loading dock equipment of a Distribution Center operating 24/7 will indeed require more scheduled maintenance than a loading dock operating 5 days a week only on a single shift.

If you happen to have qualified personnel among your staff, you can implement a daily maintenance routine, and if more complex work is required, do not hesitate to contact a loading dock specialist. Another very important thing to do is to keep a record and safely store the dock leveler model and serial number for future reference and keep copies of all service work done per dock position.

In conclusion, regular maintenance not only helps prolong the life of your loading dock equipment, but will definitely improve efficiency, circumvent accidents caused by equipment failure and prevent downtime to maximize facility productivity and profitability.

Loading dock safety and efficiency is a matter that concerns all members of any business. Here at Loading Dock Inc, we have improved the operation and safety of loading dock equipment in New York City Metro and New Jersey areas for more than 40 years. We have provided the reliability and resources needed for our customers to handle the continuously evolving needs of the material handling industry.

Not only do we provide maintenance services, but we also sell a variety of dock equipment, such as loading dock doors, dock levelers, dock seals and shelters, vehicle restraints, and a large variety of parts and accessories. We have a full line of loading dock equipment you can see on our website in case you need a replacement. Our mission is to provide our customers with the highest quality equipment in order to maximize their safety and productivity at their facilities.

For more information, please contact our sales and maintenance team. You can call at 201-249-6247, or email us at info@loadingdock.com. It will be a pleasure to assist you.

.png?width=127&height=90&name=LDI%20Logo%202025%20for%20website%20header%203%20(1).png)