It is a serious safety hazard for a trailer to pull away from your loading dock while your forklift operator is still inside. A vehicle restraint (also known as truck restraint and dock lock) is a piece of equipment installed at the loading dock that is intended to prevent a transport vehicle from leaving the dock during the loading/unloading process. A vehicle restraint can also help keep your very expensive trailer and cargo at the dock where it belongs rather than disappearing as soon as you leave for the day.

Vehicle Restraint, Truck Restraint, Dock Lock

Vehicle Restraint, Truck Restraint, Dock Lock

Table of Content:

1. Why Is It Important to Install a Truck Restraint?

2. What Kinds of Truck Restraints Are There?

2.1 Wheel Chocks

2.2 Light Communication Systems

2.3 RIG Vehicle Restraint Systems (Dock Locks, Truck Locks)

2.4 Wheel Engaging Vehicle Restraints

3. Manually Operated Truck Restraints vs Powered Operated Truck Restraints

3.1 Manually Operated Truck Restraints (Vehicle Restraints)

3.2 Powered Operated Truck Restraint (Vehicle Restraints)

4. Common Terms and Definitions for Vehicle Restraints (Dock Locks)

1. Why Is It Important to Install a Truck Restraint?

It is important to install a vehicle restraint safety system to prevent unscheduled truck departures at the loading dock. These are designed to lock a truck/trailer in the proper position at the loading dock during loading or unloading, these also provide visual safety in communication between the truck driver and the attendant of the loading dock.

In the following video, you'll see an example of the vehicle restraints that we're proud to offer to our customers.

2. What Kinds of Truck Restraints (Vehicle Restraints) Are There?

There are many different kinds of vehicle restraints (dock locks) such as:

2.1 Wheel Chocks

2.2 Light Communication Systems

2.3 RIG Vehicle Restraint Systems

- Manual Operated Vehicle Restraints

- Automatically Operated Vehicle Restraints (Power Operated)

2.4 Wheel Engaging Vehicle Restraints

2.1 Wheel Chock:

The most basic type is a wheel chock which can be utilized with or without a light communication package (mentioned below). A wheel chock can be a simple block of wood, form-fitted rubber/laminate wedge chock, or constructed of plastic or metal alloy. A wheel chock is manually placed in front of one or more of the trailer's wheels in an attempt to restrict the trailer's movement during the loading/unloading process.

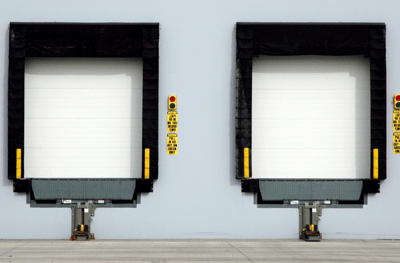

2.2 Light Communication Package

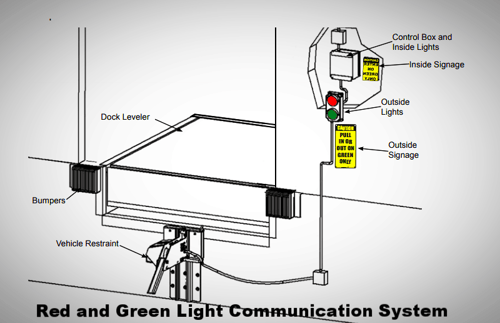

A light communication package can stand alone, be combined with a simple wheel chock, or be integrated with a vehicle restraint system. A common system would include an interior and exterior “red” and “green” lighting system designed to enhance the communication between dock operating personnel and transport vehicle drivers. A set of signs are frequently added to indicate when it is safe to enter the trailer or pull away from the dock area. The lighting sequence can be manually or automatically activated.

2.3 RIG Vehicle Restraints/Truck Restraints:

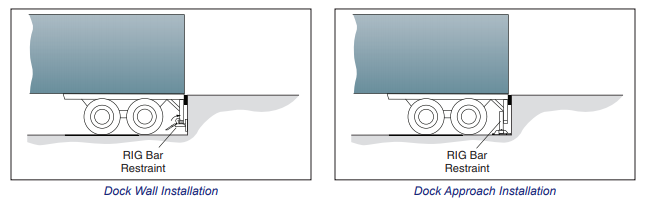

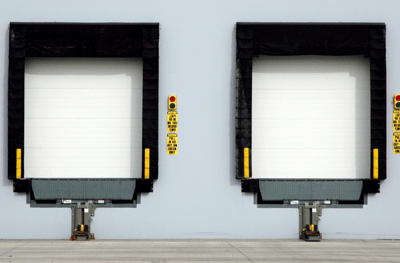

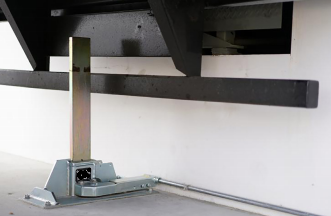

This is by far the most common type of vehicle restraint. It is designed to engage the RIG bar common to most transport vehicles. It does this by either blocking the bar (rotating hook) or forming a vertical obstruction, preventing the vehicle from moving away from the dock until the restraint is released by the dock operator. These restraints are typically mounted to either the dock wall or to the drive immediately in front of the dock, but can also be recessed in the building structure under the dock pit as well.

- Manual Operated Vehicle Restraints

- Automatically Operated Vehicle Restraints

2.4 Wheel Engaging Vehicle Restraints/Truck Restraints

This type of restraint acts by engaging one or more of the tires of the transport vehicle. Wheel engaging restraints are frequently used in applications where the transport vehicles being serviced do not have RIG bars or RIG bar is obstructed, such as lift gate trailers or small city delivery vehicles.

3. Manually Operated Vehicle Restraints vs Powered Operated Vehicle Restraints (Dock Locks)

Vehicle restraining devices (also known as truck restraints or dock locks for trailers) are further classified according to manual versus powered operation:

3.1 Manually Operated Vehicle Restraint (Dock Locks, Truck Restraints):

A vehicle restraining device that is both engaged and released manually. While less expensive than powered equipment, manually operated units depend on the dock operator to typically use a rod-like device to engage and disengage the unit. A light communication package that may be part of a manual restraining device can be manually or automatically sequenced.

3.2 Power Operated Vehicle Restraint (Dock Lock):

A vehicle restraining device that is both engaged and released through a powered means. This is the most popular type of restraint in that the operation is simple and easily accomplished. The restraint is operated by either a simple push-button or is automatically engaged as part of an overall integrated dock system. A light communication package that is part of a powered operated vehicle restraining device is generally sequenced automatically.

4. Vehicle Restraint Common Terms and Definitions

Learn about the most common vehicle restraints and truck restraints terms and definitions to fully understand what you need to know to choose the best vehicle restraint for your application.

- Automatic Vehicle Restraint: placement of a vehicle restraint device in its operating position by powered means not initiated by the loading dock operating personnel.

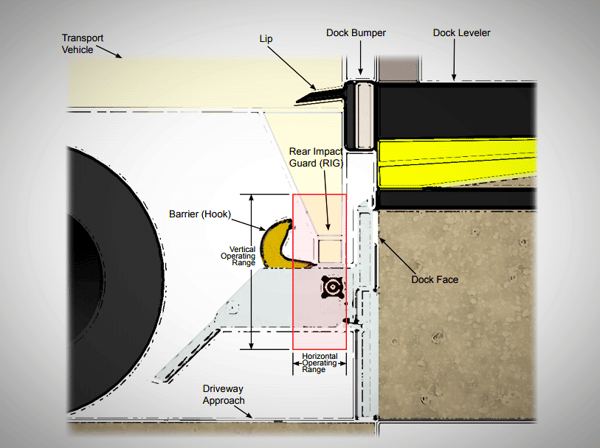

- Barrier (Hook): the portion of a vehicle restraint device that engages the transport vehicle to prevent movement.

.png?width=200&name=Poweramp%20Vehicle%20Restraint%20with%20Hook%20(Barrier).png) Vehicle Restraint's Barrier (Hook)

Vehicle Restraint's Barrier (Hook)

- Bumpers: Dock bumpers are used to prevent the transport vehicle from contacting and damaging the building, dock leveler, or vehicle restraint. They are usually made of rubber. Dock bumper sizes and projections vary, based on vehicles serviced and other factors such as driveway slope.

- Chock: to place a wheel chock in front of a wheel of a transport vehicle to inhibit movement of the vehicle away from a loading dock.

Wheel Chock

- Communication Light System: colored lights to communicate the status of the loading operation to the dock operator and to the driver of the transport vehicle. Typically one set of lights is visible to the dock operator to indicate whether the restraint is engaged, and another set of lights is visible to the transport vehicle driver to indicate whether it is safe to pull the vehicle away from the dock. The lights are typically green to indicate “GO” and red to indicate “STOP”. Amber lights may be used to indicate caution.

- Dock: This is the area of a building where loading and/or unloading of transport vehicles takes place.

- Dock Bumper: See Bumpers

- Dock Face: vertical surface at the front of a dock projecting from the driveway to the dock floor.

- Dock Level: This term involves the vertical level that conforms to the building’s floor surface.

- Dock Leveler: A dock leveler is a device affixed to a dock structure to form a bridge between the dock structure and a transport vehicle, thus allowing movement of industrial vehicles between the transport vehicle and the dock structure.

- Dock Lock: It is another way of calling vehicle restraints.

- Dock Pit: The pit is the recessed opening in the building’s floor that accommodates the pit dock leveler. Most pits are lined along the edges with structural steel angles that are embedded in the concrete.

- Dock Mounted Restraint: a vehicle restraint mounted to the dock structure, usually the face of the dock.

- Driveway: the surface in front of the dock where the transport vehicle is parked. The driveway surface may be generally horizontal or maybe sloped toward or away from the dock. The driveway surface is typically made of concrete, asphalt, or gravel.

- Driveway Mounted Restraint: a vehicle restraint mounted to the driveway surface rather than to the dock.

- Hook: It is the portion of a vehicle restraint device that engages the transport vehicle to prevent movement (also called "barrier").

.png?width=200&name=Poweramp%20Vehicle%20Restraint%20with%20Hook%20(Barrier).png) Vehicle Restraint's Hook

Vehicle Restraint's Hook

- ICC Bar: see “Rear Impact Guard (RIG)” Industrial Vehicle: forklift trucks, powered or non-powered pallet jacks, or any other form of vehicles used to load or unload material on a transport vehicle.

- Industrial Vehicle: forklift trucks, powered or non-powered pallet jacks, or any other form of vehicle used to load or unload material on a transport vehicle.

- Light Communication Package: typically a red and green light system that can be activated manually or automatically. Intended to improve communication between loading dock operating personnel and transport vehicle driver.

- Lip: The lip assembly is usually pivotally attached to the deck assembly and pivots from a vertical stored position to a position that rests on the transport vehicle’s floor. Lips are usually made with a tread plate that is similar to the deck.

- Loading Dock: building area or structure where goods are moved to and from a transport vehicle. The dock is usually elevated above a driveway where the transport vehicle is parked.

- Loading Dock Operating Personnel: a person or persons engaging in the process of loading and/or unloading transport vehicles whereby the activities may include the operation of industrial vehicles, dock levelers, vehicle restraints, dock doors, etc.

- Manual Operation: placement of a vehicle restraint device in its operating position by the manual effort of the loading dock operating personnel.

- RIG Bar Restraint: a vehicle restraint that engages the rear impact guard (RIG) of a transport vehicle, thus preventing movement of the vehicle away from the dock structure.

- (RIG) Rear Impact Guard: a structure attached to the rear of a transport vehicle to prevent an automobile from running under a transport vehicle during a rear-end collision (a.k.a. ICC bar or underride guard). As of January 1998, U.S. federal motor vehicle safety standards FMVSS 223 & FMVSS 224 regulate the performance and use of rear impact guards for trailers rated over 10,000 pounds Gross Vehicle Weight (GVW).

- Transport Vehicle: a cargo-carrying vehicle (e.g., a truck, semi-trailer, trailer, or railcar) that may be entered upon by a powered or non-powered industrial vehicle or conveyors to load or unload material.

- Underride Guard: See “rear impact guard”.

- Unscheduled Departure: the event of a transport vehicle departing the dock before loading or unloading is completed.

- Vehicle Creep: the movement of a transport vehicle away from the loading dock caused by the transfer of momentum as an industrial vehicle decelerates when entering the vehicle and accelerates when exiting the vehicle. Uncontrolled trailer creep may allow the lip of a dock leveler to become unsupported and create a dangerous gap between the transport vehicle and the dock.

- Vehicle Restraining Device: a device affixed to a dock structure or a driveway to engage a transport vehicle.

- Vertical Operating Range: the range of heights of the bottom of a RIG above the driveway that can be engaged by the vehicle restraint. See “working range”

- Wheel Chock: a block, usually wedge-shaped, which is placed on the driveway in front of a wheel of a transport vehicle to inhibit movement of the vehicle away from a loading dock.

- Wheel Restraint: a vehicle restraint that engages one or more wheels of a transport vehicle, restraining uncontrolled movement of the vehicle away from the dock structure.

- Working Range: the horizontal and vertical range of positions of a RIG that can be engaged by the vehicle restraint.

Get Additional Information - Contact Us

Now that you know the common terms and definitions used in vehicle restraint, make sure to call the best technicians of Loading Dock, Inc. for loading dock equipment repair, maintenance, and installation.

For more information, please give us a call at 973-471-4060 or email us at info@loadingdock.com

![]()

We service Northern New Jersey (Bergen, Passaic, Union, Essex, Morris, Hudson, Hunterdon, Somerset county/counties), Manhattan, New York City, Brooklyn, Queens, Staten Island, Bronx, Westchester, and Rockland.

.png?width=127&height=90&name=LDI%20Logo%202025%20for%20website%20header%203%20(1).png)