A truck restraint, often referred to as a dock lock, plays a crucial role in preventing a truck from shifting during the loading and unloading process. If a truck departs the loading dock prematurely, there is a risk of workers sustaining severe injuries or even fatalities and potential damage to freight and equipment. Familiarize yourself with the main dock lock systems used for trailer restraint to enhance safety and operational efficiency at a loading dock.

A trailer restraint should be able to interlock with a powered dock leveler, preventing the leveler from functioning when the vehicle isn't secured. If there's no RIG bar or the restraint can't engage with it, an alternative method like wheel chocks must be employed. The attendant needs to use the override function to enable the dock leveler in such instances, ensuring the vehicle's wheels are chocked for safety. Trailer restraints are available in two designs:

A trailer restraint should be able to interlock with a powered dock leveler, preventing the leveler from functioning when the vehicle isn't secured. If there's no RIG bar or the restraint can't engage with it, an alternative method like wheel chocks must be employed. The attendant needs to use the override function to enable the dock leveler in such instances, ensuring the vehicle's wheels are chocked for safety. Trailer restraints are available in two designs:

RIG Dependent (RIG Bar) Vehicle Restraints RIG Dependent (RIG Bar) Vehicle Restraints |

Wheel Chocks Wheel Chocks |

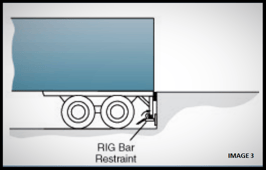

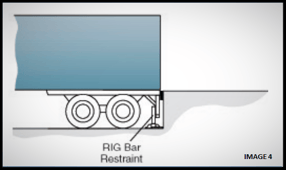

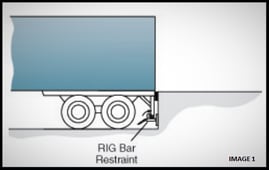

1. RIG-Dependent Vehicle Restraints

The RIG-dependent system stands out as the most widely used type of trailer restraint. Leveraging the prevalence of rear impact guards (RIG bars) on over-the-road trailers, these systems employ a rising barrier. This barrier captures the trailer's RIG bar, effectively utilizing it to lock the trailer securely in place. (Image 3 and Image 4).

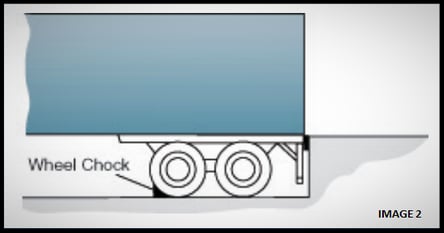

A powered-activated restraint can use programmable controls providing versatility in coordination with various loading dock equipment. In a powered-activated restraint system, a RIG restraint engagement sensor is standard, while it is an optional feature in a manual restraint system. A manual wheel chock, a tapered block positioned in front of the wheels, serves to prevent unintended movement.

RIG-dependent restraints are available in manual and powered activation designs. These restraints can engage underride guards from 7-1/2 to 30 inches off grade. A manual restraint uses a push bar to raise and lower the release latch on the restraint.

An activated restraint powered by push buttons utilizes an electric motor, pneumatic cylinder, or hydraulic pump and cylinder for the elevation and descent of the restraint (refer to Image 5). This type of restraint can employ a control system that provides adaptability in coordination with various loading dock equipment.

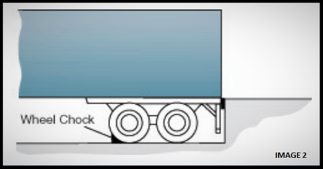

2. Manual Wheel Chocks

A manual wheel chock is a tapered block strategically placed in front of the wheels to thwart unintended movement. Unlike underride-dependent systems, wheel chocks offer universality. They can effectively secure trailers equipped with underride guard systems, hydraulic lift gates, tandem hitches, or damaged guards. All loading docks should be equipped with wheel chocks for added safety.

Disadvantages Of Manual Wheel Chocks:

- Dockworkers might consider them impractical and may neglect using them.

- If misplaced or stolen, securing the trailer becomes impossible.

- Their manual placement can be a time-consuming process.

- Unlike wheel chocks, a standard RIG vehicle restraint can withstand forces exceeding 30,000 lb, proving more effective in preventing unintended trailer departures.

Aside from using vehicle restraints such as wheel chocks and RIG-dependent restraints to safeguard your workers, you can rely on the prompt and trustworthy services provided by our professionals at Loading Dock, Inc. We offer swift and dependable solutions for your loading dock equipment such as dock levelers, dock scissor lifts, dock bumpers, and dock shelters.

For more information, please give us a call at 973-471-4060 or email us at info@loadingdock.com

![]()

We service Northern New Jersey (Bergen, Passaic, Union, Essex, Morris, Hudson, Hunterdon, Somerset county/counties), Manhattan, New York City, Brooklyn, Queens, Staten Island, Bronx, Westchester, and Rockland.

.png?width=127&height=90&name=LDI%20Logo%202025%20for%20website%20header%203%20(1).png)