There are many reasons why you may need to replace a dock leveler (also known as dock plates) as they, like the bridges, are used over time and although they may seem like a long-lived piece of equipment, they eventually wear out. Sometimes a simple dock leveler repair may be enough.

Dock Leveler Basics

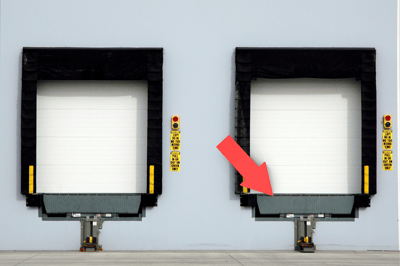

Dock levelers are used where a building has a truck-level door. Pit-style dock levelers are fixed to loading docks. The most common dock leveler design is stored in a recess or dock pit, beneath the dock door and the floor, that’s why it is called a recessed or pit dock leveler.

Dock levelers are either controlled manually with a pull chain, known as mechanical dock levelers, or controlled hydraulically, known as hydraulic dock levelers. Hydraulic dock levelers are controlled through an electric pump that drives a piston to lift the plate and another that moves the lip which is a metal plate that raises from the dock and then lowered onto the back of a truck. Some lips are hinged, and others are telescopic.

Other types of dock levelers are:

Main Reasons for Replacing a Dock Leveler

✓ The leveler wants to lift up as it’s driven over

✓ The top deck is warped

✓ You’re updating your loading bay

✓ You’re looking to upgrade from a manual dock leveler to a new leveler operated with an electrical control panel

✓ The lip is bent or warped

✓ The dock leveler will not operate properly

✓ It no longer meets your loading requirements

✓ It is time (hydraulic dock levelers have a 10-year life expectancy)

Dock Leveler’s Preventive Maintenance

Regardless of the frequency in which the equipment is used, maintaining the proper operation and safety of your dock leveler and related equipment should be a number one priority.

There exists a great number of replacement parts and numerous upgrades available for both, hydraulic dock levelers and mechanical dock levelers.

Mechanical dock levelers (also known as manual dock levelers) use springs that are always under pressure, that is why greater maintenance requirements and a more frequent need to replace parts will be necessary, especially for spring as they are also sensitive to heat and cold which make a constant adjustment when temperature changes over seasons.

Signs of dock leveler damage include:

- Broken seals surrounding the door, allowing moisture to enter.

- When it is not opening or closing smoothly.

- “Sticking” of the door

- Visible dents, bends, or other structural damage to the door.

Dock Leveler’s Replacement Parts

Some of the many kinds of dock leveler replacement parts you may need or desire to upgrade include:

→ Dock Bumpers

Dock bumpers eliminate cutting or damage to the leveler’s force-absorbing rubber material and reduce friction, while significantly increasing abrasion resistance, for reduced wear and tear on the bumper. While decreasing friction also significantly minimizes vertical stress on the anchor bolts securing the bumper.

If you have rubber bumpers, you will need to replace them at some point or upgrade them to steel-faced dock bumpers, which spread the impact from docking vehicles over a far greater surface area. By doing these, you assure longer life for dock bumpers and heightened integrity of the installation.

→ Springs & Hold-Downs

Mechanical dock levelers are powered by coiled springs, which push the dock leveler up. The hold-down keeps the leveler at the proper height when not in use. If the paws, paw springs or ratchet fails, the leveler will stay in the “up” position, and if the springs fail, you won’t have the force to lift the leveler. When these kinds of things happen, these parts must be replaced to ensure proper operations of the leveler.

→ Full Range Toe Guards

They span the complete travel range of a dock leveler and are not required on mechanical dock levelers.

→ Dock Track Guards

Track guards offer a barrier to protect the overhead door track from impact during truck loading/unloading and are designed for automatic and mechanical doors. Track Guards are tapered at the top to prevent pinching of items while the door is closing. They mount both the floor and wall for extra durability and strength.

→ Below-Level Controls

This is a pull ring/chain affixed to the dock leveler deck. When the ring is pulled, the dock leveler extends so the leveler can be positioned below level. You will need to replace this equipment if it breaks from use and wear and tear.

→ Hydraulic Pump Parts

Maintenance of the pump for your hydraulic dock leveler is also essential. If the leveler makes a strange sound when activated, there may be an issue with the hydraulic pump. You may need to repair or replace related parts.

→ Lip Assist Assembly

If you cannot make your dock leveler’s lip appear, you may have a broken lip assist assembly. You should have this equipment repaired or replaced.

Time to replace your dock leveler? Contact us. We have mechanical, hydraulic, air-powered, and vertical dock levelers. For more information, call at 973-471-4060 or email us at info@loadingdock.com.

For 24/7 emergency service call: 973-471-4060.

![]()

We've been selling, installing, repairing, and serving loading dock equipment in New Jersey and New York City Metro area for over 40 years. Contact us. Our experts will be more than happy to assist you.

We service Northern New Jersey (Bergen, Passaic, Union, Essex, Morris, Hudson, Middlesex, Hunterdon, Mercer, and Somerset county/counties), Manhattan, New York City, Brooklyn, Queens, Staten Island, Bronx, Westchester, and Rockland.

.png?width=127&height=90&name=LDI%20Logo%202025%20for%20website%20header%203%20(1).png)