SEALING SYSTEMS FOR COMMERCIAL AND INDUSTRIAL OVERHEAD DOORS

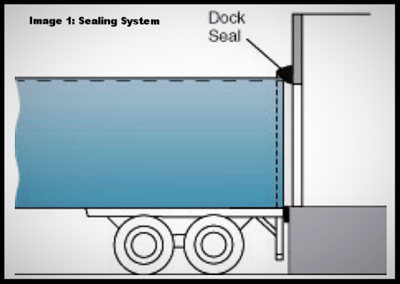

Sealing systems seal off the space between a parked trailer and the building (Image 1). They help to maintan the internal climate, and they protect the freight against damage. Find out the top 2 sealing systems for overhead loading dock doors & gates here.

Sealing systems have many benefits:

- Energy savings ─ The system can quickly pay for itself in reduced heating and cooling costs by maintaining the building’s interior temperature.

- Safety and productivity ─ Eliminates dangerous precipitation from the loading areas. Worker productivity correlates to the workplace environment and its safety.

- Freight protection ─ Protects freight against harmful weather and minimizes entry of vermin.

- Security ─ Prevents product theft and unauthorized entry.

- Storage ─ Docked trailers become secure, climate-controlled extensions of the building.

There are two types of sealing systems:

- Compression foam dock seals ─ The seals are made of foam covered with fabric. They are mounted to the wall at the loading door and seal against the back of the truck.

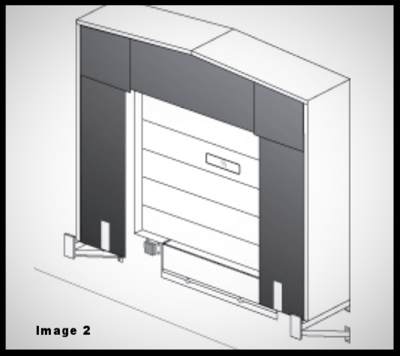

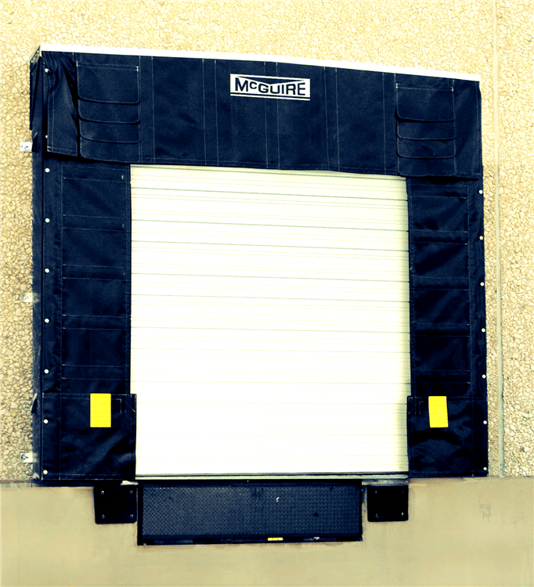

- Truck shelters ─ They have a rigidor flexible frame equipped with curtains. The frame is installed to the building wall. The curtains extend and seal against the wall and the rear of the truck (Image 2).

Both seals and shelters use abrasion-resistant industrial fabrics on their sealing surfaces due to the trailer movement during loading and unloading. The wall construction may determine the most suitable type of sealing system. Dock shelters are most suitable where walls are not designed to handle the high compression forces of traditional seals.

SELECTION CRITERIA FOR SEALING SYSTEMS

Proper selection is the most important aspect of sealing system installation. Improper selection can result in not only a poor installation, but also product damage and decreased productivity. When selecting a sealing system,

choose a system that is the most effective at sealing the majority of vehicles being serviced.

1. Grade of Approach

The grade of approach might be level, declined or inclined. If necessary, seals can be tapered to ensure parallel compression along the entire face of the side pads, which creates an effective seal.

2. Overhead Door Dimensions

The size of the door opening determines the most suitable sealing systems.

3. Dock Bumper Projection

The dock bumper projection is the distance between the wall and the front face of the bumper. On declined driveways, the dock bumper must project far enough to prevent trucks from impacting the upper wall.

4. Dock Height

The dock height is the distance between the grade and the top of the dock floor.

5. Mounting Surface

The wall construction may determine the most suitable type of sealing system. Dock shelters are most suitable where walls are not designed to handle the high compression forces of traditional seals.

COMPRESSION FOAM DOCK SEALS

Compression foam dock seals are more effective for sealing than using a shelter system. Compression foam dock seals have limitations:

• Cannot be used on doors wider than 9 ft

• Only accommodate a narrow range of trucks

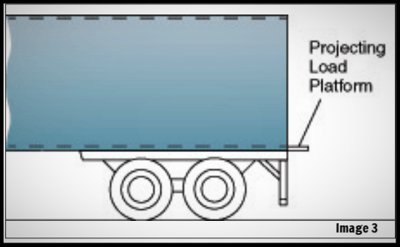

• Do not work well with trucks with rear loading platforms (Image 3)

• Limit access to interior of the truck

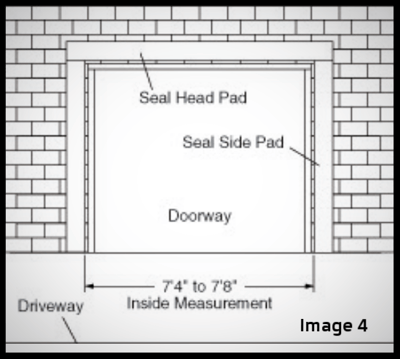

Install the seals with an opening between 7’4”and 7’8” (Figure 4). Use bevel seals for a loading door wider than 7’8” (Image 5).

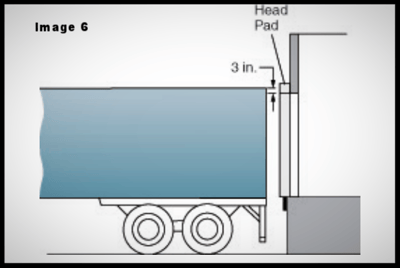

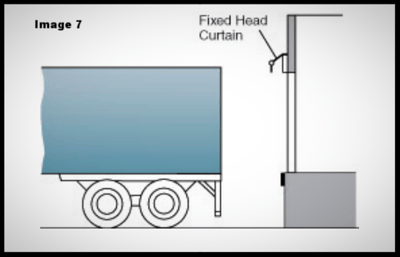

Maintain a minimum of 3 inches between the bottom edge of the head pad and the top of the truck (Image 6). Adjustable head pads are available. Use a fixed head curtain instead of head pads for tall doorways and a wider range of trailer heights (Image 7).

Guidelines for compression foam dock seals installation:

• Per square foot of pad length - approximately 80 lb of compression force on building

• Distance from wall to the face of the dock bumper - minimum of 4 in.

• Pad projection beyond the bumper - Minimum of 4 in., maximum of 8 in.; 6 in. is nominal

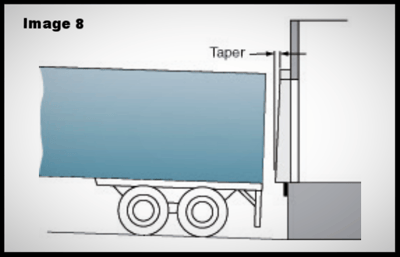

• For recessed driveways with a slope of more than 2% - specify a taper seal. For every 1% of driveway grade, taper the seal 1 in. for overall length (Image 8).

TRUCK SHELTERS

A truck shelter allows for full access to the interior of the truck. An air gap will still be present around the hinge area of the truck’s door.

Dock shelters can be installed on nearly any door, but are usually installed on doors between 9 ft wide x 9 ft high and 12 ft wide x 12 ft high.

A truck shelter allows for full access to the interior of the truck. An air gap will still be present around the hinge area of the truck’s door. Dock shelters can be installed on nearly any door, but are usually installed on doors between 9 ft wide x 9 ft high and 12 ft wide x 12 ft high.

Use truck shelters for:

• Loading doors wider than 9 ft or higher than 10 ft

• Trucks with extended tailgates

• Trucks with rear platforms (Image 3)

• Full access of truck’s interior

Guidelines for truck shelter installation:

• Minimum shelter width ─ 11’6” (O.D.) measured across the side frames

• Standard opening width ─ 7’ measured between the insides of the side curtains

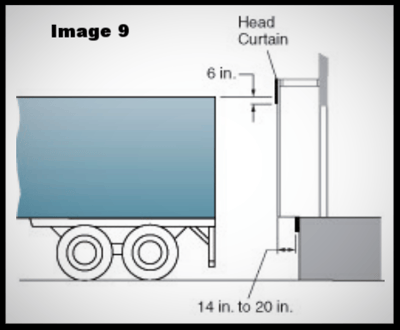

• Position of bottom edge of head curtain ─ 6 in. below height of the lowest expected truck

(Image 9)

• Top of shelter ─ minimum of 18 in. above top of highest expected truck. Commonly 15 ft off top of grade.

• Shelter extension in front of dock bumpers ─ 14 to 20 in. Increase the extension to 20 in. minimum for shelters wider than 12’ 0”.

• Install the support brackets for a rigid shelter on the building foundation, flush with the dock floor. The support brackets should project past the shelter frame by 6 in.

Loading Dock, Inc. Dock Seal and Truck Shelter service photos:

Our expert technicians at Loading Dock, Inc. deliver cost-effective maintenance, repair, and installation services for loading dock seals and shelters, ensuring reliable performance and long-lasting protection.

Book a Service Call Now!

Need service for your worn and damaged gate and loading dock door sealing system? The hardworking servicemen of Loading Dock, Inc. are always ready to provide durable and efficient loading dock door seals and shelters for your loading dock doors & gates.

For more information, please give us a call at 201-249-6247 or email us at: info@loadingdock.com We service Northern New Jersey (Bergen, Passaic, Union, Essex, Morris, Hudson, Hunterdon, Somerset county/counties), Manhattan, New York City, Brooklyn, Queens, Staten Island, Bronx, Westchester and Rockland.

.png?width=127&height=90&name=LDI%20Logo%202025%20for%20website%20header%203%20(1).png)